Manufacturing process

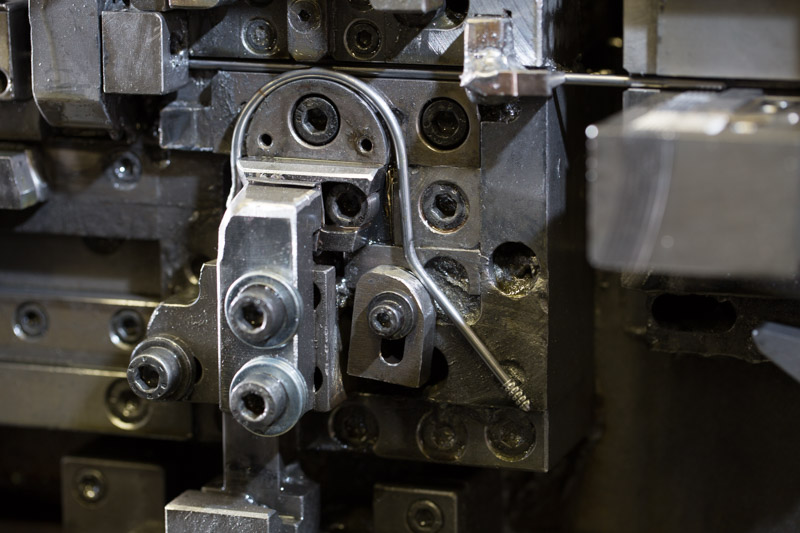

Moulding and Bending:

it is the initial process, which transforms raw material into the desired product. We have approx. 90 machines that do this – some work wire, some strip, as well as mechanical presses that shear and mould sheet steel.

Hardening:

with three automatic lines for hardening, we can transform the product through the heat treatment process of hardening and tempering and make it of the desired hardness.

Galvanizing:

two completely automatic lines are for galvanizing – we can offer several levels of resistance to corrosion, according to requests.

Coating:

coating was introduced few years ago, with liquid or epoxy powder. We have a wide range of colours available according to customer needs.

Quality Control:

different equipment controls product quality – from measurement of raw materials to clip hardness, from wire resistance to clip endurance tests, from deformation resistance of hooks to salt spray tests for corrosion resistance.